|

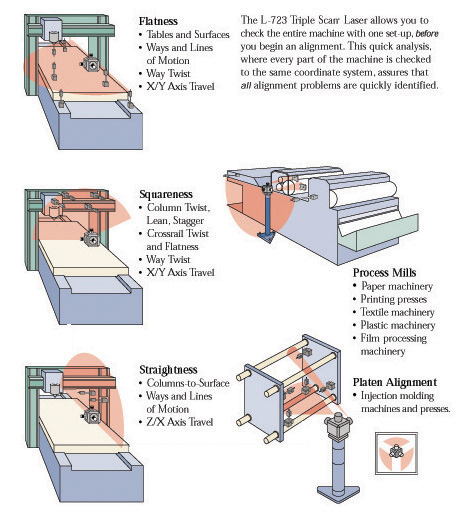

Mill Alignment Service Welded tube Pros offers laser assisted mill alignments for welded tube mills and metal rollforming lines. Please select the appropriate category below. Tube Mill Alignments Rollformer Alignments Alignment References Equipment other then welded tube mills and rollformers may be aligned with our laser. Contact us for more information. Principals of Laser Alignment Operation The pictures below describe the many ways that the 3 plane laser may be utilized.

Images and info: Hamar Laser Instruments Inc. Used with permission. The Principals of Operation The laser alignment system used by Welded Tube Pros measures 3 axis machine geometries by automatically sweeping 3 ultra flat laser planes (like a ceiling and 2 walls). These planes are mutually square to each other to within 1 arc second. The projected laser beam is sensed by a laser target, which records the position of the surface being measured relative to the projected laser plane. When the beam hits the target it creates an analog signal, which is converted to a digital number. The number is displayed on a handheld readout. The numerical readout is accurate to 0.0001". The readout shown is preset to show 0.001" accuracy. Positions are read +/- relative to the laser beam.

To measure or align machine geometries, the laser plane is made parallel to 3 reference points (3 points define a plane). This is referred to as "bucking in". The pitch and roll of the laser plane are adjusted by using course and fine micrometers built into the base of the laser.

|