|

Rollforming Mill Alignments

Your Cold Rollforming mill is a tool holder. When rollshaft shoulders are out of alignment so are the tools mounted on them. Operating without the proper mill alignment accelerates wear on roll tooling. Operating without the proper mill alignment increases change over time (A change over is NOT complete until you are running good product). Operating without the proper mill alignment reduces shape quality. Operating without the proper mill alignment increases the odds for employee injury. Operating without the proper mill alignment breaks roll tooling and rollshafts. Operating without the proper mill alignment breaks cutoff dies and blades. How much does downtime, poor roll life, broken rolls / shafts STEAL from your profits? Are you satisfied with your current changeover times?

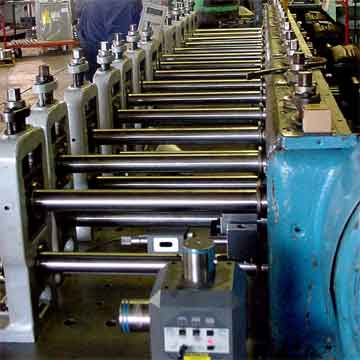

Photo of a laser alignment system on a typical 14 pass rollform mill.

Get the clear picture! Don't guess! Misaligned roll shafts can't be seen only the results show themselves! Welded Tube Pros Three Plane Laser assisted mill alignment service gives a clear picture of mill component condition and tells you what repairs are needed in one setup!

Why use a laser to do an alignment?

Q. How do geometry lasers work? A: Systems consist of a laser, targets and data display. Lasers emit flat planes and/or lines that are aligned to a machine's datum or to gravity (level). They provide a reference to measure other points using position-sensitive laser targets. The data display shows the deviations and provides alignment correction instructions in real time.

Q: What geometric characteristics are measurable? A: Straightness, perpendicularity, flatness, parallelism and concentricity. Applications include: Roll shaft shoulders, Roll shaft parallelism, Weld Box location, Cutoff centering, Drive coupling and Sheave alignment.

Q: How precise is laser measurement? A: The accuracy is within .00004" in 5' depending on the laser . This is equivalent to slicing the thickness of a sheet of paper 75 times. In Tube / Pipe mill environment laser alignments are performed to 300 foot overall distances in one setup with a repeatable accuracy reading to + / - 0.001".

Q: Why use a laser system? Optical methods seem to work well. A: Optical alignment methods are slow, less accurate and only tell you what's wrong. Geometry lasers are easier to set up, simpler to use and show you how to actually fix alignment problems. Laser position measurement readout is digital with no interpolation by a single operator.

Q: Machine manufacturers never mention the need to realign my machine tools; is alignment really necessary? A: Yes. Normal wear and tear, vibration, metal fatigue, temperature, humidity changes, accidents, and many other conditions can cause misalignment.

In the words of Mike Breen, Field Service Engineer for Ellison Machinery Company: "Nothing saves more money than aligning your machines. The tooling (mills, drills, and inserts) is very costly, and alignment greatly increases tool life." (Source: Modern Application News, August 2001). Click Here to See Pictures of a Mill Alignment Click Here to see a sample mill alignment report

|