|

Paste Weld Detectors For Welded Tube Acoustic Resonance - How Electro Magnetic Acoustic Resonance Works Resonance describes the natural phenomenon of periodic vibration patterns that occur in all matter. This elastic or traveling wave is demonstrated in the vibrations generated when a tuning fork is struck. Only the vibrations that are reflected between the surfaces of the tuning fork that precisely overlap become additive in intensity and are emitted as an audible sound. The tone emitted is the resonant, acoustic signature that carries within it a complete physical description of the tuning fork including material composition, shape, temperature, and notably its properties of quality or precision in manufacturing.

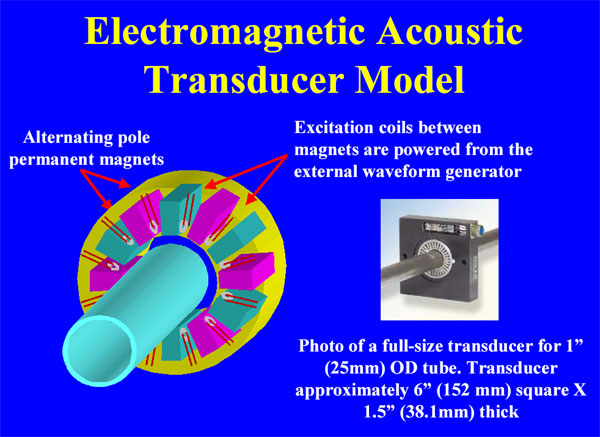

Transducer unit with small diameter tube passing through it EMAR or Electro Magnetic Acoustic Resonance is a unique method of generating resonance. The ARIS technique utilizes an EMAT or Electromagnetic Acoustic Transducer specifically designed and optimized to generate high frequency resonance, The transducer generates surface currents in the material under test similar to eddy current techniques; independent magnetic manipulation of these currents converts these currents into sound waves. What is revolutionary in the application of the RM-EMAT is the control of vibrational patterns and frequency’s of the resulting resonance. This gives control over what features are to be examined and also enables the acoustic field to remain tightly focused within the vicinity of the transmitting transducer enabling small defect resolution in large structures or continuos production environments. The absence of physical contact with the test material results in the generation of an absolutely pure acoustic signature enabling measurements of acoustic properties not previously attainable or reproducible in actual practice. More important to the industrial environment is the lack of contact provides the ability of using resonance to test rapidly moving material such as wire, tube, sheet, etc. In concept this process is equivalent to that of a high-speed acoustic CT scan

In operation resonance is repetitively generated in time spans as short as .003 of a second. Detection of an anomalous condition such as a crack, density, hardness or dimension is then a process of automating the instrumentation and monitoring process via microprocessor. The anomalies can be identified by tracking the resonant frequency and measuring deviations or changes in this frequency beyond a specified range of normal resonance particular to those generated by the specific transducer configuration and material under test. Pipe and Tube All metals, extruded, welded shapes. Encircling vs flat transducers. Analytical capabilities for pipe and tube: Hardness / annealing: Sensitivity to 1.2 Rockwell Plating integrity: Thickness to 3 microns Outer diameter and inner diameter defects: ASTM compliant Outer diameter and inner diameter measurement: encircling transducers only Paste or cold weld Weld alignment Delaminations

Applicable case studies and technical documents: These are PDF files and require Adobe Acrobat Reader for viewing.

1.

Multiple

Analyses on Welded steel tubing Our HistoryResonic NDT Systems, Inc. formerly Resonic Technology Inc., was incorporated in June of 2004 to continue production of the patented Resonance Mode Electromagnetic Acoustic Transducer (RM-EMAT) and the Acoustic Resonant Inspection System (ARIS) product line. The ARIS system and testing technique are the result of more than a decade of research and development. Resonic has a long history of research collaboration with NIST. Patented Technology Soon after the laboratory demonstration of the efficacy of the physical principals of this unique approach to the determination of materials characteristics R&D began on producing an industrially hardened instrument. The first of three US Patents was issued in late 1998. Two additional patents have been recently issued with additional patents pending. Realizing the global market potential international patent filings are in process. These patents are under license to Resonic NDT Systems. Technological development is continuing and additional IP filings will be pursued as this emerging technology continues to evolve. Patents in use by Resonic NDT include: U.S.

5,808,202 |