|

Mill Alignment Photos Close-up photo of our laser inspection head and machine base as applied in a welded tube mill rollshaft shoulder alignment inspection. In order to insure accuracy, our laser system is re-certified by the manufacturer on a yearly basis. Welded Tube Pros generates an alignment report to aid in benchmarking your equipment.

We suggest quarterly inspections for tube mills running three shift per day or doing short run production demanding multiple roll changes per day. Click here for alignment references.

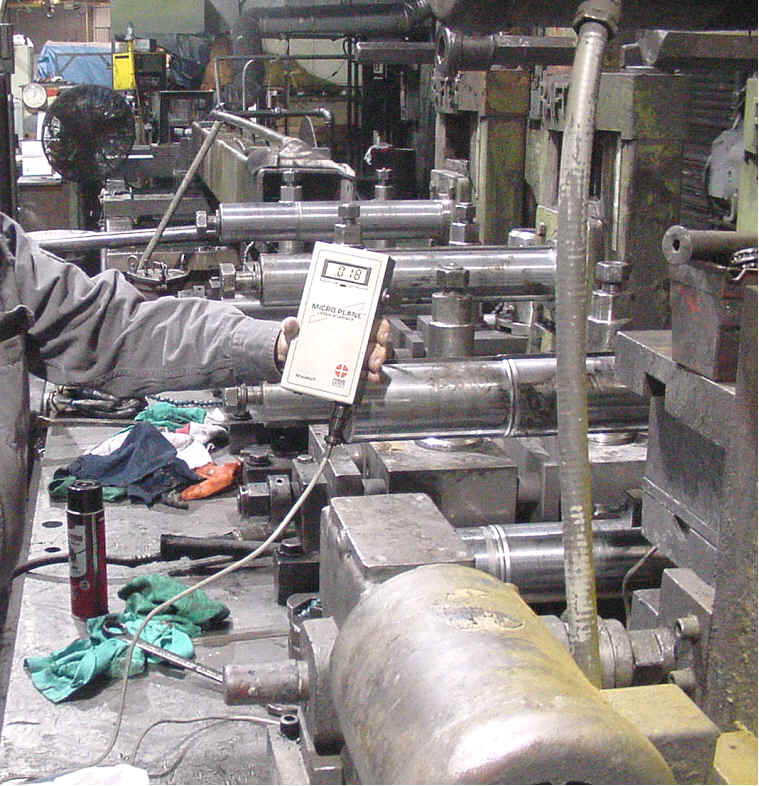

View of a typical laser setup for rollshaft shoulder alignment inspection. The laser is leveled to the machine base and the target is affixed to the rollshaft and held rigidly against the shoulder by a magnetic base. The digital readout is accurate to 0.0001". For this inspection the readout is set to only show three decimal places. The readout is digital, showing plus or minus relative to the laser scan plane.

This photo shows the measured offset in the bottom rollshaft shoulder for the last sizing pass. The laser beam is sweeping through the tube clearance path from the breakdown through the weld box, cooling trough and all sizing passes. The laser emitting instrument is approximately 125 feet upstream of this location and the readout is stable and repeatable.Contact Welded Tube Pros for a proposal on Mill Alignment inspection, operator training and related operations. |