In-Line Gauge Control

Welded Tube Pros experience in strip handling & storage for welded tube, pipe, cold roll forming and stamping processes are now married with I²S (Integrated Industrial Systems) capabilities to provide the best possible patented in-line gauge and camber controls for today’s high speed, high precision, welded tube, roll forming, and stamping lines.

In-Line Gauge Control offers the welded tube

producer a process to consistently reduce conversion losses, improve

profitability, and produce superior tubular products with potential sales

opportunities in new markets without extensive capital investments. The

application of the process to Welded Tube production is not limited, by

materials, by weld speed or by material thickness.

In-line control permits the use of the widest possible raw material

sources (steel chemistry and basic physical quality must be similar), thereby

permitting further flexibility in raw material purchasing. The process

offers, in some instances, further savings by permitting substitution of

alternate materials, for example HRS P&O for Cold Rolled.

In-Line Gauge Control offers tube producers the ability to be more

competitive and less dependent on their steel suppliers.

Tube Production Objectives through the Application of In-Line Gauge Control

Provide Reactive Control of Tube Wall in ERW Tube Production. Give the operator the ability to CHANGE the incoming gauge and correct camber conditions. Permit Consistent Production of HIGH QUALITY Tube Products. The operation that does not provide quality products will be gone! Provide the capability to use Alternative raw materials. Upgrade hot rolled gauge tolerances so it can be substituted for cold rolled, where surface finish is not a requirement.

The chart above shows a recap of actual measured thickness readings before and after gauge correction.

The upper graph depicts variation of the strip prior to gauge correction.

The lower graph shows the result of gauge correction.Before Correction: Average 0.0056", Range 0.0075" , Stand. Dev. 0.0021, Cp 0.1551, CpK -0.8676

After Correction: Average 0.00001", Range 0.0010", Stand. Dev. 0.0001, Cp 2.2880, CpK 2.2880

Reduce raw material cost.

Upgrade HRS P/O gauge tolerance so it can be substituted for cold rolled where surface concerns are an issue. Upgrade low carbon steel to the strength requirements of a higher carbon or a medium carbon to that of HSLA.

Reduce Production Cost, Increase Profits.

Maximize utilization of the available personnel skills and raw material! Reduce waste. Maintain labor cost while Increasing production. Increase profits.

What is In-Line Gauge Control?

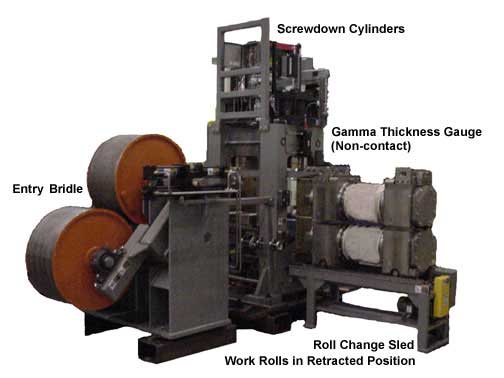

An operator controllable process to maintain material thickness entering the tube mill. With non-contact thickness measurement at the exit of the tube mill, a closed loop control can automatically adjust entry strip thickness. A self-correcting thickness control that adjusts for both variations in strip thickness and hardness once set by the operator. An automatic process that can also reduce strip camber problems while correcting thickness variation.

Why Use Gauge Control?

Reduce roll wear and reduce set up time by providing uniform strip thickness with reduced camber variation. Permit purchase of commercial grades in lieu of close thickness tolerance. Permit substitution of material grades. Actively make Tube Walls to +/- 0.0005" of desired wall. The process converts over gauge material to thinner and longer sections. On strip widths common to small tube production, the vast majority of material growth is to length, with normal reductions being 10% or less. Below is shown a rolling study performed on 6" X 0.257" thick, low carbon, hot rolled. The width growth for a reduction of 8% would be on the order of + 0.1 to 0.2%. As strip width increases the growth in width decreases.

The

experience of I²S

I²S

has the largest engineering staff of all U.S. mill builders. With over 1000

years (combined) of experience in the mill industry, our employees have worked

for the following mill companies: Sendzimir, Waterbury Farrel, Fenn, Ruesch,

Loewy, Fagersta Steel (Sweden), Salem Stainless Steel (India), Ulbrich Stainless

Steel, Chase Brass, American Brass, Scovill Brass, Century Brass, Stanley Steel,

Torin Company, Cold Metal Products, Superior Steel, HMSS Sczopience (Polish

Brass), Republic Steel, SMS, Wean, and Tippins Machinery. Over

30% of our staff is engineering. Our engineering staff is comprised of

professionals specializing in software, electrical, mechanical, hydraulic,

coolant and structural design. Equipped with some forty CAD stations, which are

networked together, each engineer, designer and drafts person has a precision

drawing tool in their hands. Access to all the drawings for a given project is

provided by our Windows NT based computer network. This facilitates precision

engineering and ensures the accurate implementation of design changes on each

project.

Mechanical engineering personnel are grouped by equipment categories to allow

them to exchange knowledge and operate efficiently in a single area. The project

leader is fully supported by members of specific groups which focus on designing

and detailing of systems such as hydraulics or coolant. Members from all of

these areas join to form a team for the duration of each project.

Each I²S mill is custom designed around your needs. In the design process we

employ the newest computerized geometric element analysis (GEA) technology.

Solid modeling is used to make accurate predictions in mill components such as:

mill housings, winder shafts, rolls, etc.. GEA allows exact geometries to be

modeled accurately. The data derived from the analysis enables the engineer to

identify critical areas of the part and compensate in the design to achieve the

acceptable stress and deflection values for its application. I²S engineering

means quality equipment designed for longevity and safety.

For more information - CONTACT US

Please view the articles below:

In-Line Gauge Control in Welded Tube Production - By W.B. 'Bud' Graham

From the Tube and Pipe Journal, July 2001.

Equipping a Modern Tube Mill Part 1 - By W.B. 'Bud' Graham

From the Tube and Pipe Journal, July & August 2001.

Equipping a Modern Tube Mill Part 2 - By W.B. 'Bud' Graham

From the Tube and Pipe Journal, September 2001.

Articles to download: These are Adobe PDF files.

For a free copy of Adobe Acrobat Reader, click below.